April 12, 2018

In 2017 Oil and Gas provided 76% of the UK’s primary energy and 60% of that came from indigenous sources. BP and Shell have reported revenues of $240.2 Billion and $305.1 Billion , respectively, keeping oil and gas as one of the UK’s biggest industries. Being a huge and relatively old industry, oil and gas corporations are prime for disruption from new technologies. AR and VR have already seen application in other sectors and there are a number of ways that they could revolutionise oil and gas. So here are 5 ways that AR and VR are going to change the oil and gas industry.

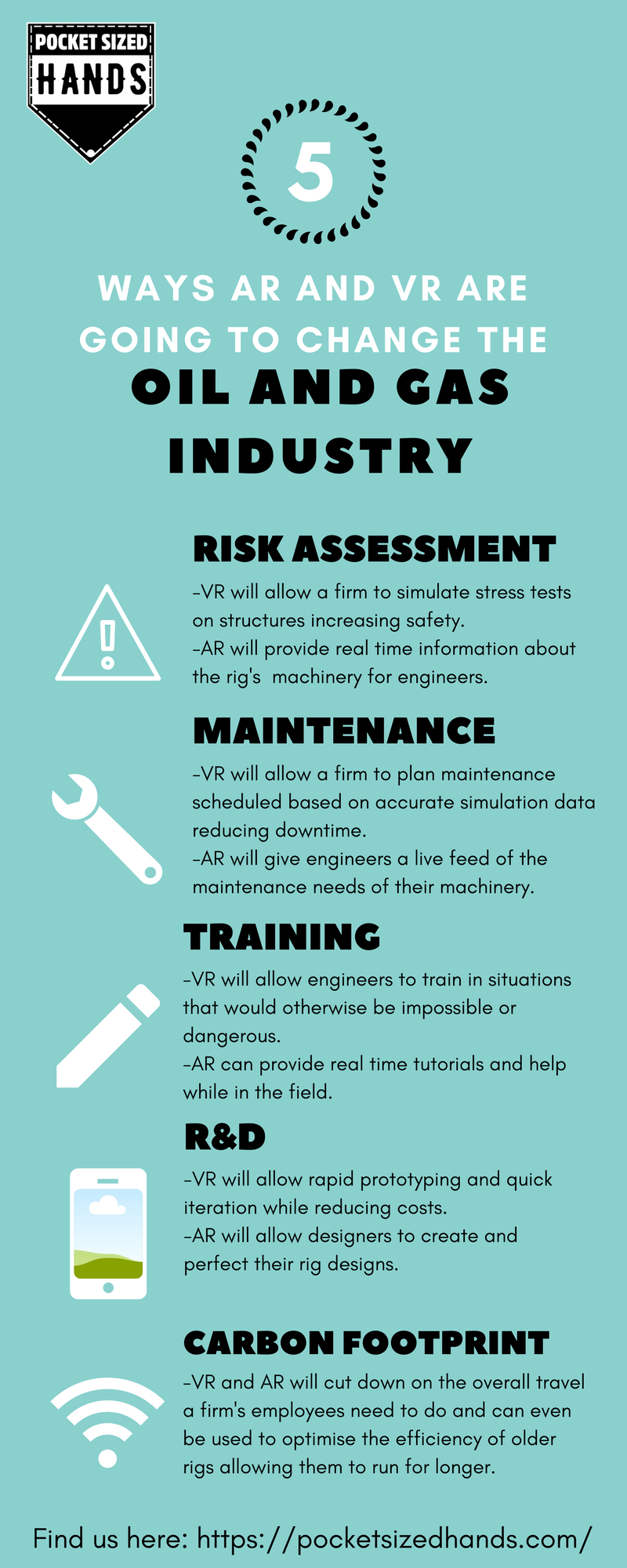

1. Risk Assessment

The operations undertaken by O&G firms are incredibly risky endeavours. Risk management and assessment are an important part of any business whether you’re grooming the pooches of the Hollywood elite or trying to send your favourite electric car to Mars. O&G sits closer to the latter on this particular spectrum of risk with an off-shore rig costing upwards of $200 Million to set up. $200 Million to set up. Virtual and augmented reality technologies offer new ways to mitigate the risks involved with these business activities. VR’s main function is to simulate an environment digitally and this would prove invaluable to the O&G industry. Simulating the construction and operation of a new oil rig and the surrounding environment could be used to test how the rig would perform in different scenarios with a wide range of stressors and variable to ensure that the rig is safe to use and that production wouldn’t be adversely affected by any of the conditions. This could help to save firms money, with reduced downtime, and more importantly this use of VR could save lives by helping designers to detect events that could cause catastrophic failure on the rig. In a similar way, augmented reality technology would give an engineer an enhanced view of the equipment that they are working with on the rigs. An overlay, provided by a headset or mobile device, could be used to show live updates on tools and equipment letting the engineer know what to do to prevent an emergency situation and, if needs be, let them know what to do in the event of one. AR would also provide an improved communication platform, allowing engineers to collaborate with one another and with others off the rig while working so they can share their own knowledge and expertise.

2. Maintenance

The maintenance of rigs is one of the main causes of downtime and lower rates of production. It is also an incredibly important part of the O&G industry as it keeps the rigs safe and productive in the long run. VR and AR have applications in this area that could help boost the productivity of rigs while also minimising downtime. A VR simulation could be made that shows the path of the drill and the operations of other technology and the information gleaned from these sims could be used to predict potential problem areas and help create an optimised maintenance schedule. Used as a planning tool, VR would be incredibly useful to an O&G firm allowing them to be proactive instead of reactionary which would save them money and help prevent accidents or malfunctions occurring. As was said before, augmented reality would be utilised best by engineers on the rigs. Using the readouts on their overlay they would be able to monitor the efficiency and integrity of the equipment in front of them. This would allow them to react in real time with information that wouldn’t normally be available to them, meaning they would be able to work smarter and be able to keep the rig running at peak efficiency with greatly reduced downtime. The improved communications would also help with maintenance as the engineer would be able to consult with other experts around the world on what the correct course of action should be while they are on site.

3. Training

Training is a huge cost to any firm , let alone one that is focused on highly technical and specialised work like that which is undertaken on a daily basis by rig workers. There is only so much theory and practical work that you can do while onshore, eventually you will need to send engineers offshore and this can be incredibly expensive or hazardous depending on where the rig is located. VR and AR can change that. VR will allow you to place engineers in situations that would otherwise be impossible to emulate while keeping them onshore. They can practice their skills in complete safety before heading to the rigs. This will allow you to send them offshore, confident in their abilities and this will help mitigate any reservations that senior engineers may have about having less experienced colleagues on board. It will also save the firm money as they don’t need to pay for the constant travel of trainees and instead would only need to invest in a the simulation application and VR headsets which would cost them less in the long run. Augmented reality could be used on and offshore as a training tool. It could be used to improve the quality of existing training by providing enhanced information to the engineers as they perform their tasks. Real time tutorials would help improve the overall quality of training, offering advice and tips while the trainee attempts the task. Once offshore the trainees and even senior engineers could receive regular checkups on their abilities to ensure that they are always at the top of their game.

4. Research & Development

R&D is essential in every industry. Planning and creating competitive advantages will make or break your business. VR and AR technologies have the capacity to play a pivotal role in allowing O&G firms to craft these advantages. Earlier we mentioned that VR could be used as a risk assessment tool. What better time to test for risk than the research stage? A firm could quickly and easily prototype rig structures and see how they fare in multiple scenarios, this would allow for fast iterations on design and facilitate the creation of incredibly efficient and robust solutions. Having an application tailor made for this purpose would save your firm money in the long term as you will be able to avoid costly mistakes. AR is a great tool during the conceptual stage of any design situation as it allows you to create and manipulate 3D objects in front of your very eyes. You could create and scrutinise every aspect of a rig model and pinpoint any areas that may prove problematic in the future and allow you to save on your R&D budget as you are nipping problems in the bud instead of finding out when it’s too late. The AR display could also offer other viewers information on the models in front of them, allowing you to easily communicate and work with others on projects all over the world which is a huge boon for multinational firms.

5. Carbon Emissions

In a past blog post we talked about lowering carbon emissions by leveraging AR and VR technologies technologies . O&G firms could stand to benefit the most from applying these practices. As we talked about before, VR and AR could be used to reduce the amount of traveling that employees would need to do which can take a huge chunk out of the carbon footprint of a firm. Training employees can take place entirely on shore if needs be, office employees could work from home and digitally commute to meetings and scrums using these new technologies. Couple this with the increased mobility that your work force would gain and you now have a formidable team of experts that can be wherever you need them instantaneously. And there you have it, 5 ways that the oil and gas industry will be changed by the application of VR and AR technology.

As always If you have an idea you want created get in touch with us and we can bring it to life. Whether it’s a quick prototype, a full product or even just to brainstorm, our team will be here to help. From the beginnings of your prototype to the final product we can support you with professional advice and delivery.